csm nano hardness tester|nanoindentation tester nht3 : white label The Nano Indenter ® G200 system is an accurate, flexible, user-friendly instrument for nanoscale mechanical indentation testing. The G200 measures Young’s modulus and hardness, including measurement of deformation over . Erome escola. 11002 Visitas* 0 Total . 0% . Descrição. HD. Erome. 12003 visitas Avaliação : 0% 12 min . Catarina Paolino erome . Todos os modelos tinham mais de 18 anos na .

{plog:ftitle_list}

WEBLive Games Providers. There are not so many providers of bitcoin live casinos. There are less than 10 of them on our platform, but our partnership with them has brought a lot of great games to the category. Here are the crypto Live Casino providers on BetFury: Pragmatic Play Live, BetGames, Evolution, Ezugi, Vivogaming.

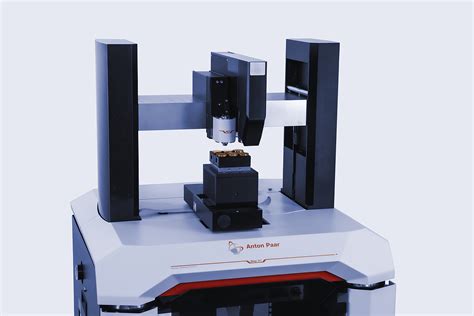

The NHT³ Nanoindentation tester is designed for measuring hardness, elastic modulus, creep, and other surface properties from the nanometer to the micrometer scale. Its force ranges from .

With Anton Paar’s versatile indentation testers you can precisely determine the .The Nano Indenter ® G200 system is an accurate, flexible, user-friendly instrument for nanoscale mechanical indentation testing. The G200 measures Young’s modulus and hardness, including measurement of deformation over .With Anton Paar’s versatile indentation testers you can precisely determine the mechanical properties –e.g. hardness and elastic modulus – of thin films, coatings and bulk materials. The instruments can handle almost any type of .Ultra nanoindentation tester UNHT³ measures the mechanical properties of coatings and bulk materials such as hardness and elastic modulus as well as viscoelastic and creep properties from the nanoscale. . Combine the UNHT3 .

The equipment is the latest version of the CSM-Nano Hardness Testing system, which offers enhanced capabilities in testing a wide range of manufactured or even soft biological and polymeric materials. It can provide modulus and hardness values under dynamic or creep loading protocols. Impression creep features of some materials have already . The hardness testers are especially suited to penetration depth measurements at the nanometer to micrometer length scales. For thin surface coatings this is particularly important to minimise the influence of the .

conventional hardness testing to smaller length scale) - diamond indenter - indenter oriented perpendicular to the surface - variable indenter geometries; Berkovich, cube corner, . •CSM_NHT •(Nano-Hardness Tester) • Hysitron_Triboscope •CSIRO_UMIS •(Ultra-Micro-Indentation System) (Do Kyung Kim, KAIST) 13.A Nano Indenter ® G200X system was used to perform impact nanoindentation testing on aluminum, iron, stainless steel, and commercial purity magnesium. Hardness testing as a function of strain rate was compared for these materials using the ISO 14577 test method and Constant Load and Hold (CLH) testing.

Nanoindentation was carried out using ultra - nano hardness tester (CSM, Switzer- land) under load control mode up to a maximum load of 250 mN. Learn more about IHS Goldfire. Product Announcements. Durometer PCE-2000N incl. ISO calibration. PCE Instruments / .

Advanced Nano-Mechanical Testing Center Micro Indentation Tester (MHT³) Nanoindentation (NHT The Microindentation Tester is ideally suited to the measurement of mechanical properties such as the hardness and elastic modulus of thin hard coatings, thick soft coatings, and bulk materials such as PVD and CVD hard coatings and ceramic surface layers.The Nano Indenter ® G200 is used with the Express Test and the laser-heated tip and stage options for elastic modulus and indentation hardness testing of Ordinary Portland Cement (OPC) paste at temperatures from 20°C to 250°C. NanoVision was also used to generate surface topography measurements.Hit 300 is the simplest-to-use nanohardness tester on the market, featuring automated measurements, high accuracy, and a unique laser targeting system at a competitive price. . Hardness and elastic modulus of coatings can only be measured by indentation testing. Thin coatings (0.5-5 µm) are challenging because of the low indentation depths .

CSM Instruments has been leader in the development of instruments for surface mechanical properties characterization for over 30 years in both research and industrial fields. Our product line includes: • Scratch Testers: Used to measure characteristics such as adhesion of a coating, delamination effects or cracking in order to optimize coating techniques and determine failure .THE NEW GENERATION OF NANOINDENTER CSM Instruments has introduced a new nano range high resolution nanoindenter with ultra low thermal drift. When used per ISO 14577 test methods the Ultra Nano Hardness Tester will provide the .Film hardness and elastic properties can be derived using a CSM nano-indentation tester. Indentation testers are high precision instruments used for the characterization of mechanical properties of thin films, coatings and substrates. Properties such as hardness and elastic modulus can be determined on almost any type of material: soft, hard . Instrumented indentation test, also known as nanoindentation test, has been widely used to evaluate the local indentation hardness of materials at the nano- and micro-scales for academic and industrial purposes; it has been frequently compared with the Vickers hardness (HV) test used on larger scales [].A considerable number of studies have investigated the .

Fig. 6 shows representative data of the CSM indentation creep test on PTFE. To measure mean stress and contact stiffness the indenter is oscillated at a peak–peak load amplitude of 1.2 μN and a frequency of 45 Hz during the holding segment. Mean stress is the hardness measured continuously during the CSM during the hold segment. In the conventional CLR test method, only a single hardness value is obtained from each indent at the maximum depth [25]. Conversely, with the use of continuous stiffness measurement (CSM) technique in CSR tests, the hardness variation with depth can be recorded continuously during the penetration of the indenter into the investigated materials .carried out using a CSMTM nano hardness tester (NHT). mechanical properties were calculated using the Oliver and Pharr method. Scratch testing was carried out on all samples using the CSMTM microscratch tester (MST). The MST was used as a progressive loading device with a Rockwell C diamond indenter of radius of 200 µm. .Table Top Nanoindentation Tester (TTX-NHT) Description: The CSM Instruments Table Top Instrument places the performance of the standard Nanoindentation Tester (NHT) into a small and simple-to-use instrument which is ideally suited .

CSM SCRATCH TESTERS Nano, Micro and Macro range //// Adhesion and Scratch Resistance //// Conventional Hardness //// Compliant to ISO & ASTM standards . . > Nano/Micro Hardness measurement modules > Open Platform for automatic handling of samples > Vacuum, humidity and temperature controlledNANOVEA Mechanical Tester is the most versatile nanoindenter and scratch tester capable of precisely measuring the micro- to nanomechanical properties of wide ranges of materials from thin films, coatings, ceramics and composites to polymers and bio materials via Indentation, Scratch and Friction testing.. All NANOVEA Mechanical Tester models come with true feedback load .

Figure 7.4 Nanoindentation tester head (adopted from CSM NHT2 documentation). The Nanoindentation tester comprises of a high frame with stiffness (~107 N/m) which provides a high stability to the instrument. Furthermore, the Nanoindentation tester supports a wide range of loads for the testing purposes (0.1 mN to 500 mN).Certified methods are employed: nano indentation on the Nano Hardness Tester (CSM Instruments, Switzerland); and measurement of the critical load L c at which coating sections peel away on .The fatigue testing can be performed in the cyclic indentation mode to measure the fatigue/fracture life of materials. . This area is used to measure the hardness of the material. On the other hand, unloading portion of the load-depth data contains the information of the stiffness of the material being tested. . (CSM) technique is a . For nano-indentation, a diamond Berkovich indenter was used and the tests were performed at least on seven different spots using a nano hardness tester (CSM, Australia).

Nanoindentation hardness tester. Nanoindentation hardness tester is used to evaluate the mechanical properties such as hardness, elastic modulus, and fracture toughness of thin coatings. . Make: CSM Instrument (ANTON PARR Tritec) Specifications: Load range: 0.5 to 300 mN. Load resolution: 0.04 μN. Depth Resolution: 0.3 nm. MAGNETRON .

nanoindentation tester nht3

Continuous .This unique feature automatically detects and measures the area of the imprint of a conventional Vickers test and eliminates user influence on the Vickers hardness test results. The RST 300 and other Anton Paar scratch testers are the only scratch testers on the market with such advanced capabilities in conventional Vickers hardness testing.

Film hardness and elastic properties can be derived using a CSM nano-indentation tester. Indentation testers are high precision instruments used for the characterization of mechanical properties of thin films, coatings and substrates. Properties such as hardness and elastic modulus can be determined on almost any type of material: soft, hard .

vortex compression test video

20 Min - 'loira' Search - XNXX.COM

csm nano hardness tester|nanoindentation tester nht3